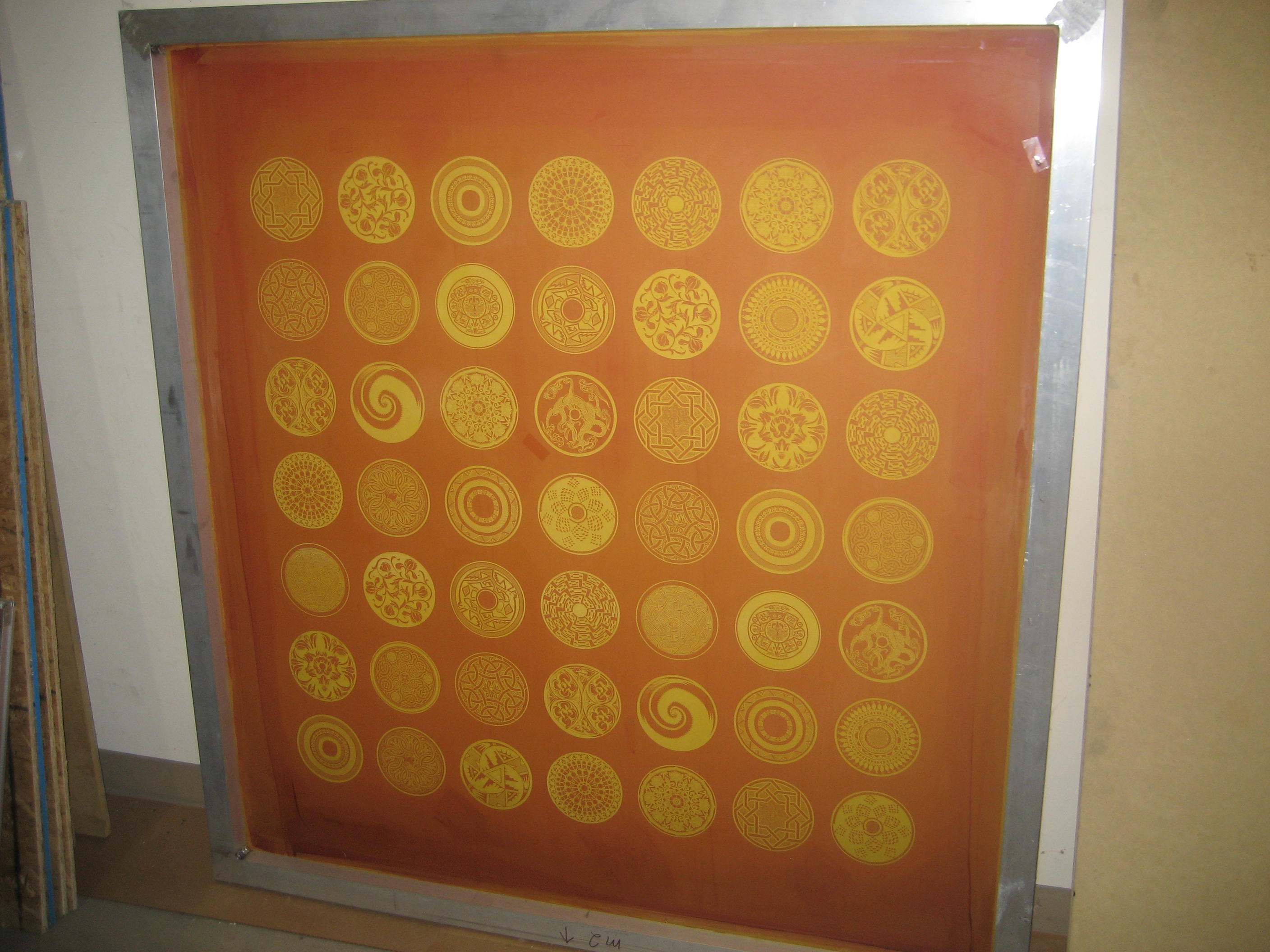

Silk Screening / Pad Printing

|

The addition of graphics onto parts is done through the silk screening process. Any critical information required for the proper use of a component are printed on painted or plated parts via this silk screening process. Silk screening provides a more elegant solution to this information requirement than the use of a stick-on label.

|

Capabilities

-

Substrates Coated

Alloys

Aluminum

Cold rolled steel

Plastic (ABS, PC, ABS/TC, Kydex, PPO, PPE, Fiberglass) -

Coatings Used

-

Work Envelope

-

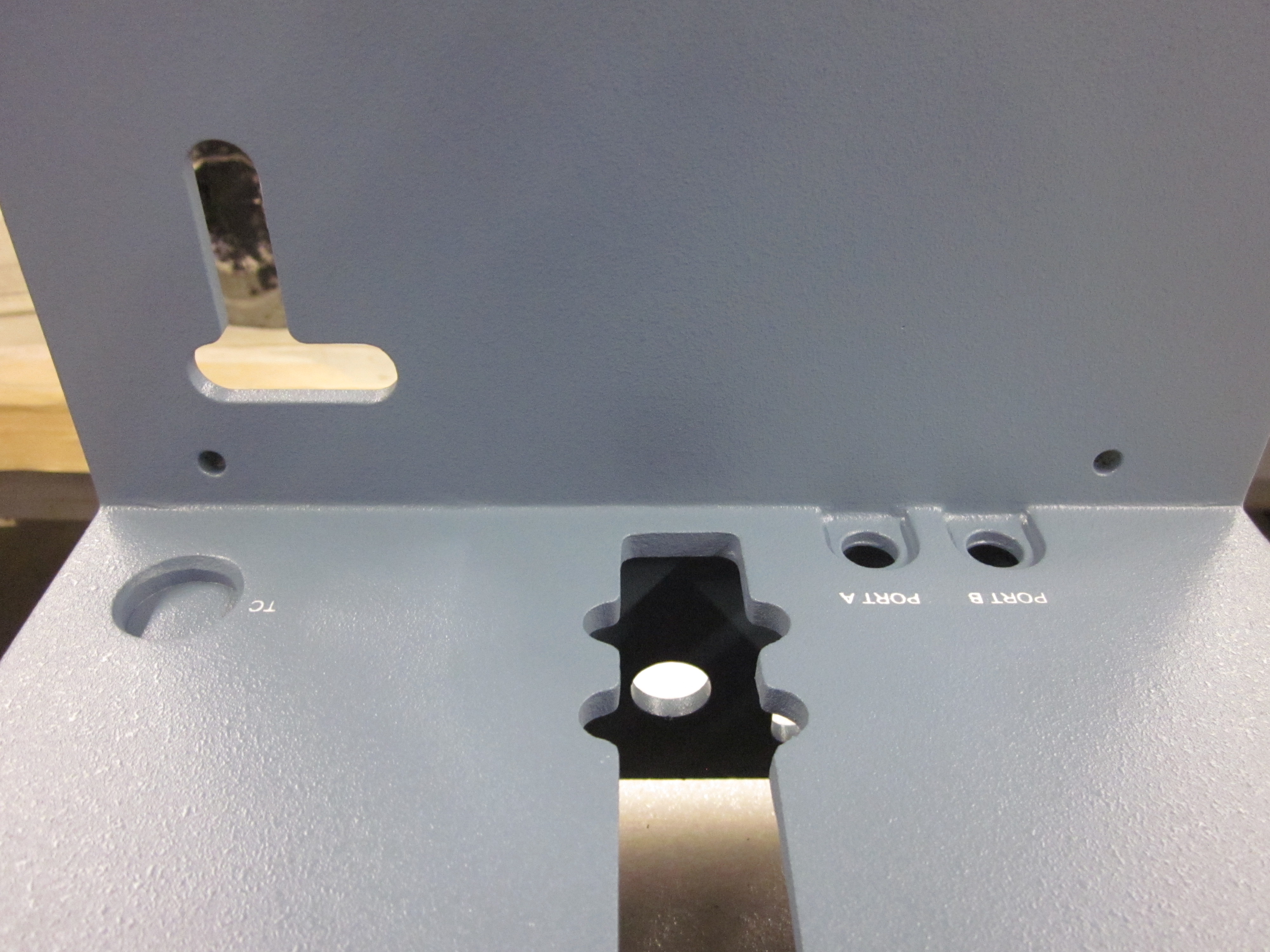

Secondary Operations

Masking

Filling/Sanding -

Industries Served

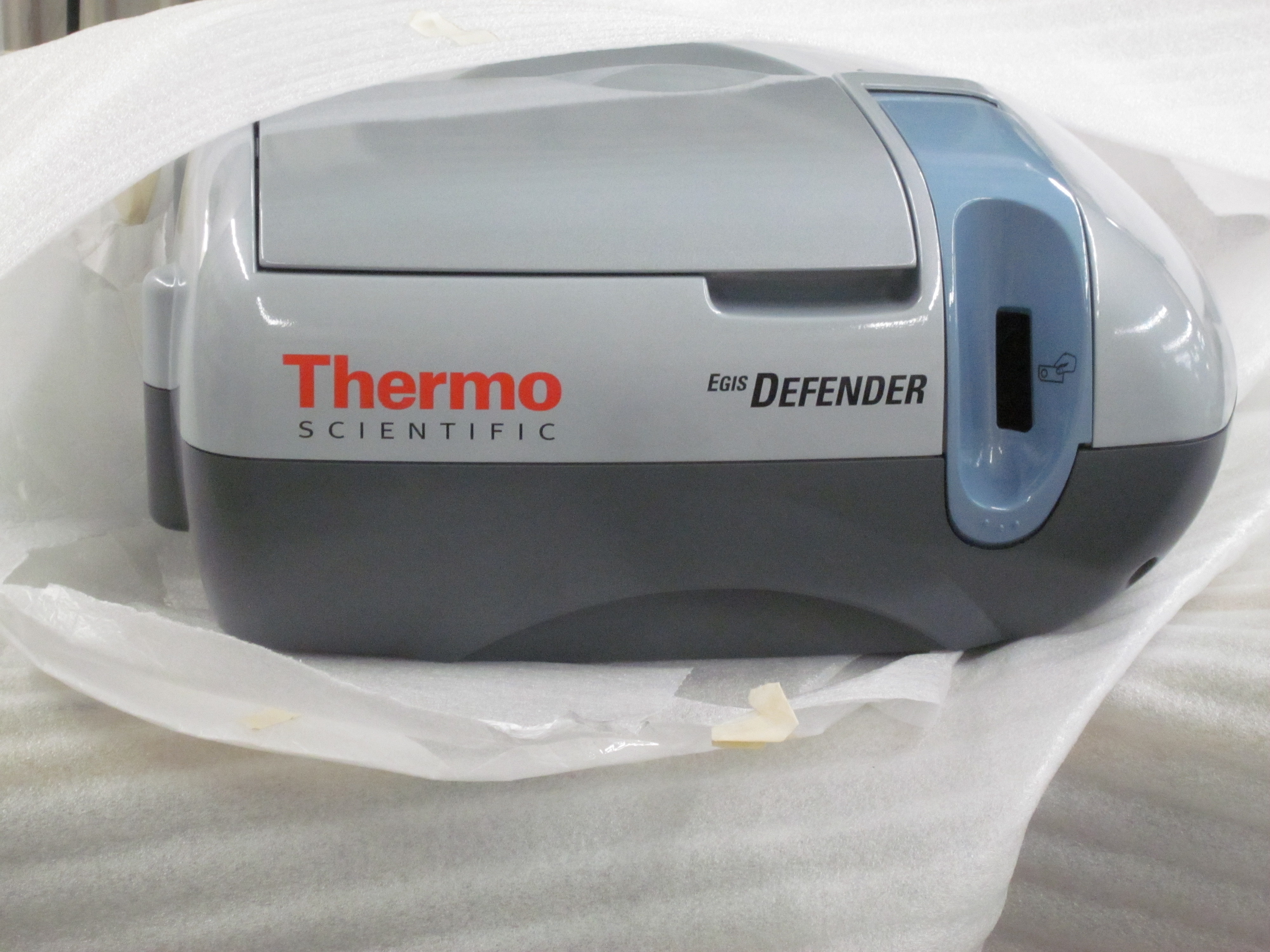

Telecommunications

Security

Gaming

Medical Instrumentation

Computer

Semiconductor

Aerospace

Fire Protection

Sporting Equipment

Laboratory Testing Equipment

Life Sciences -

Value Added Services

Short term storage of finished or unfinished products

Production planning and delivery schedules

Free local deliveries by our own transport facilities -

Equipment List

5 Overhead Conveyor Systems

13 Spray Booths

Fully Automatic 400 foot Powder Coating Line

Custom Masking Tooling

5 Stage Automatic Phosphating System