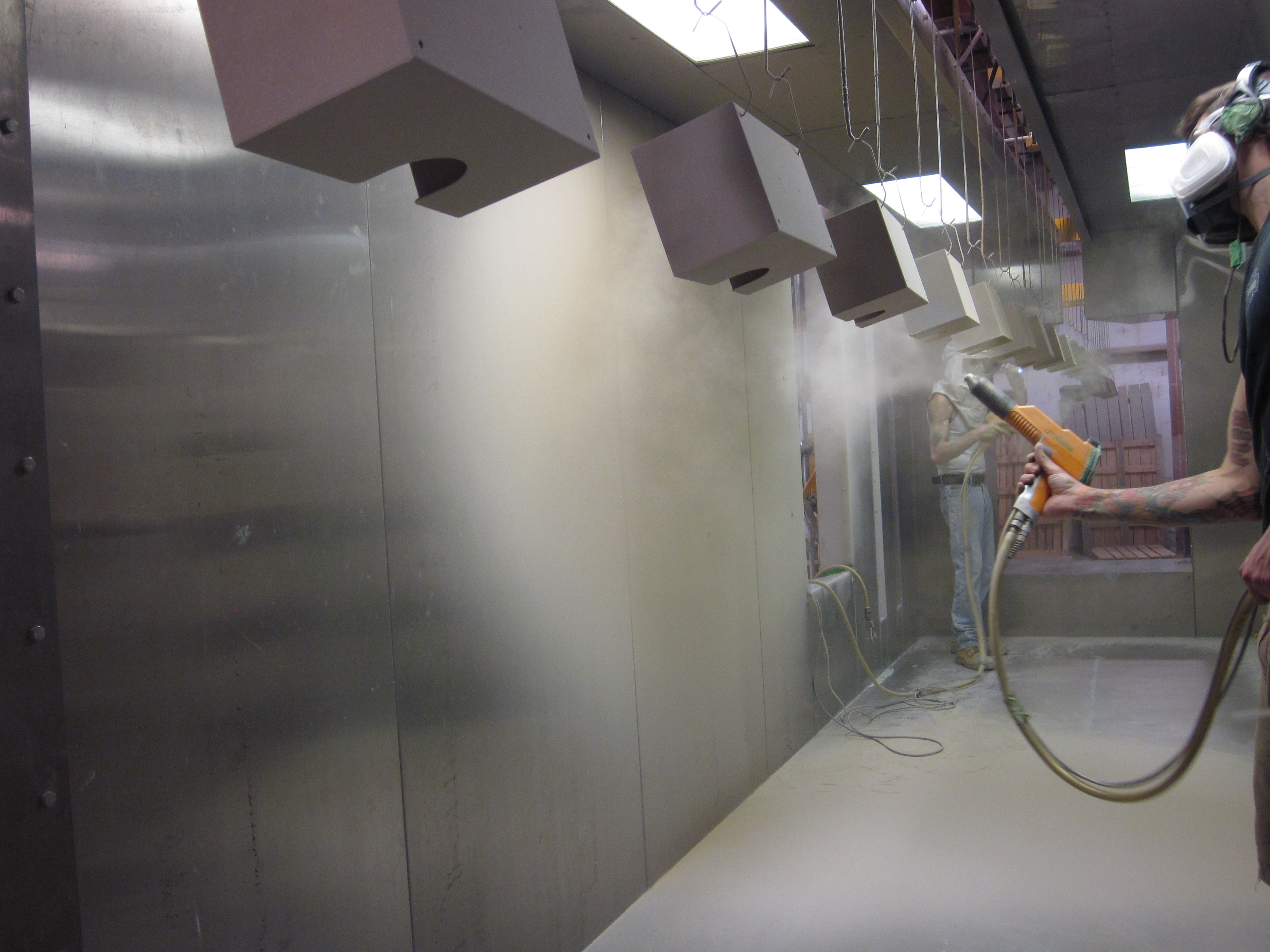

Powder Coating

|

Powder coating has gained more and more acceptability over the past decade as a surface finishing option. Powder coating offers a durable, chemical and abrasion resistant finish on a variety of substrates. Based on the chemistry of the specific powder, smooth (non-textured) and textured finishes are available in a rainbow of colors and glosses.

Frequently Asked Questions: Q. What is powder coating? A. Powder coating a type of coating that is applied as a free-flowing dry powder. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and for a skin. It is usually used to create a hard finish that is tougher then conventional paint. Q. What makes the powder stick? A. There are two make factors involved in making the powder stick. Each part is cleaned with pretreatment washer. This will remove any grease, dirt and anything else that might interfere with the painting process. Q. Why do you need to bake powder coating? A. After the parts are coated with powder, they must be properly baked within a proper temperature range. Oven heat will cause the powder to melt and form a plastic sheet around the part. Baking will give the paint durability and finish.

|

Capabilities

-

Substrates Coated

Alloys

Aluminum

Cold rolled steel -

Coatings Used

Alloys

Aluminum

Cold rolled steelSuppliers

AkzoNobel

The Sherwin – Williams

DuPont

Tiger Drylac

SprayLat

PPG -

Work Envelope

32 x 43 x 84 inches

-

Secondary Operations

Masking

Filling/Sanding

Silk Screening of Logos -

Industries Served

Telecommunications

Security

Gaming

Medical Instrumentation

Computer

Semiconductor

Aerospace

Fire Protection

Sporting Equipment

Laboratory Testing Equipment

Life Sciences -

Value Added Services

All work before getting packaged goes directly into the QC room.

Nothing is shipped unless it is perfect.

Short term storage of finished or unfinished products

Production planning and delivery schedules

Free local deliveries by our own transport facilities -

Equipment List

Fully Automatic 400 foot Powder Coating Line