PTFE, FEP, PFA, and ETFE Coatings /High Temp Coatings (Batch Oven Processing)

|

Fluorocarbon-based polymers are unique materials in that the polymer is characterized to have very low coefficients of friction and have outstanding chemical and thermal resistance properties. These fluoropolymers do play an important role in the chemistry and mechanics of how parts will function in their finished state.

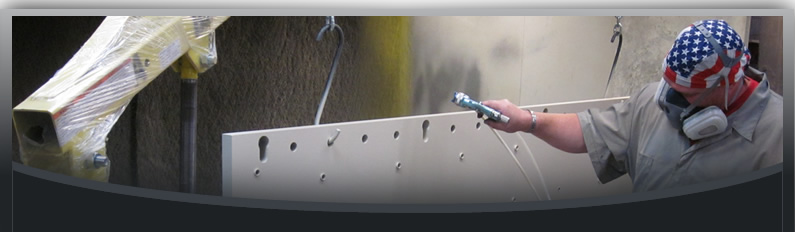

What are you looking to achieve in choosing the right fluoropolymer material for your job, and which is the most important to you? Chemical Resistance – ETFE, PFA These fluoropolymer materials generally oven-cure at high temperatures. Our high temperature batch oven allows us to cure your fluoropolymer-coated parts following the specification of the selected material’s product data sheet. Let us help you determine your fluoropolymer coating needs.

Give us a call to discuss or send us your RFQ for your fluoropolymer project. |