Industry Glossary

The following glossary contains terms used commonly in the paint and coatings industry to describe the characteristics, usage and components of paints and coatings.

A

Abatement – Involves either removal of the painted surface, covering the painted surface with an impermeable surface, or covering surface with heavy-duty coating (encapsulant).

Abrasive – Coarse material used in abrasive blast cleaning, such as sand, grit, steel shot, or glass or plastic beads.

Acrylic – A synthetic resin used in high-performance water-based coatings. A coating in which the binder contains acrylic resins.

Additives – Chemicals added to a powder coating to improve some property of a resin system such as flow control, gloss control, and texturing additives.

Adhesion – The ability of dry paint to attach to and remain fixed on the surface without blistering, flaking, cracking or being removed by tape. The surface being coated should allow a certain amount of penetration, be chemically clean, be hard, not too smooth, and non-porous, to achieve good adhesion.

Agglomerate – A clump of powder particles bound loosely together into clusters containing entrapped air.

Aerosol – A product that uses compressed gas to spray the coating from its container. Historical Note: Aerosol paint products have not contained chlorofluorocarbons–CFCs–since 1978.

Air Cap/Nozzle – Perforated housing (at the head of a spray gun or nozzle) which directs compressed air against a coating material to form and shape it into an atomized cloud.

Air Cure -One method by which liquid coatings cure to a dry film. Oxygen from the air enters the film and cross-links the resin molecules. Also called “Air Dry” and “Oxidizing.”

Air Velocity – Measurement of air speed, typically in feet per minute.

Air Volume – Measurement of air volume in cubic feet per minute.

Alkali – Caustic. Inorganic substances that share the characteristic of being strongly basic (high pH).

(Example: Sodium hydroxide or caustic soda, lye, etc.)

Alkyd -Synthetic resin modified with oil. Coating that contains alkyd resins in the binder.

Ambient – Usual or surrounding environmental conditions.

Amide – A functional group that can act as an epoxy resin curing agent.

Anchor Pattern – Profile of a surface. Usually refers to surface profile after blasting.

Anti-fouling Paint – Paints formulated especially for boat decks and hulls, docks and other below-water-line surfaces and structures to prevent the growth of barnacles and other organisms on ships’ bottoms.

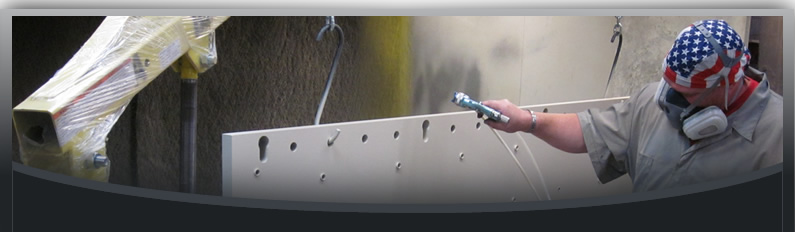

Application – Process of applying a coating to a substrate.

Aqueous – A water-based material.

Arcing – A discharge of built-up electrical charge, often in the form of a spark, to a point of lower charge, usually ground.

B

B-staging – A process describing a powder coating material that has partially reacted or cured during manufacturing or storage.

Back Ionization – A condition which may occur during electrostatic application of powder where an excessive build-up of charged powder particles limits further powder to be deposited on the substrate and can reverse the electrical charge of the surface layer of powder particles. May also be referred to as Electrostatic Rejection and/or Repelling.

(Back Ionization)

(Back Ionization)

Binder – Solid ingredients in a coating which hold the pigment particles in suspension and attach them to the substrate. Consists of resins (e.g., oils, alkyd, latex). The nature and amount of binder determine many of the paint’s performance properties – wash-ability, toughness, adhesion, color retention, etc.

Blacked Isocyanate – A curing agent for hydroxyl-containing resins. Releases the blocked agent upon reaching an elevated temperature.

Blast Cleaning – Removal of surface contaminate from a part by use of an air- or mechanically-propelled abrasive.

Blistering – Bubbles formed under a cured powder film, usually caused by the expansion of trapped air, moisture, or corrosion, either in a coating or in the substrate.

Body – The thickness or viscosity of a fluid.

Boiled Oil -Linseed (sometimes soya) oil that was formerly heated for faster drying. Today, chemical agents are added to speed up the drying process.

Bonding – Adhesion or secure joining of coating-to-coating or coating-to-substrate.

Butadiene – A gas that is chemically combined with styrene to create a resin used in latex binders, styrene-butadiene.

C

Cartridge Booth – A type of powder booth that incorporates a cartridge filter system for powder overspray recovery.

Cartridge Collector – A self-contained unit with a cartridge filter housing or box for recovery of oversprayed powder that is used with a powder booth.

Catalyst – Substance whose presence increases the rate of a chemical reaction, e.g., acid catalyst added to an epoxy resin system to accelerate drying time.

Chalking – Formation of a powder on the surface of a paint film caused by disintegration of the binder during weathering. Can be affected by the choice of pigment or binder.

Chroma – A measurement of color. The degree of saturation of a hue. A color at its full intensity has maximum chroma.

Cleaner – Detergent, alkali, acid, solvent, or other cleaning material, often water- or steam-borne, used to clean and degrease parts prior to application of powder.

Clear Coat – An unpigmented coating applied over a color or base metal such as brass.

Clear Coating – A transparent protective and/or decorative film; generally the final coat of sealer applied to automotive finishes.

Coalescent Aid – The small amount of solvent contained in latex coatings. Not a true solvent since it does not actually dissolve the latex resins, the coalescent aid helps the latex resins flow together, aiding in film formation.

Coalescent Filter – A filter used in the compressed air line to fuse and trap liquid particles in the air stream.

Coating – A paint, varnish, lacquer or other finish used to create a protective and/or decorative layer. Generally used to refer to paints and coatings applied in an industrial setting as part of the original equipment manufacturer’s (OEM) process.

Cohesion – A bonding together of a single substance to itself. Internal adhesion.

Colorant: Concentrated color (dyes or pigments) that can be added to paints to make specific colors.

Color Chip – Small piece of paper, celluloid, or other material, coated with finishing material and used as a color finish sample.

Colorfast – Non-fading in prolonged exposure to light.

Color Retention – The ability of paint to keep its original color. Major threats to color retention are exposure to ultraviolet radiation and abrasion by weather or repeated cleaning.

Compliance Coating – Coating which meets EPA defined standards for air, water, and waste disposal regulations.

Conversion Coating – Inorganic (zinc/iron phosphate) pretreatment for metal substrates that prepares the surface for powder coating.

Corona – A glowing, bluish or reddish area created by a discharge of electricity.

Corona Charging – The process of inducing a static electric charge on powder particles by passing the powder through an electrostatic field generated by a high voltage device.

Corrosion – Decomposition or reaction of metal with oxygen, water, or other chemicals, when exposed to a particular environment.

Corrosion Inhibitive – A type of metal paint or primer that prevents rust by preventing moisture from reaching the metal. Zinc phosphate, barium metaborate and strontium chromate (all pigments) are common ingredients in corrosion-inhibitive coatings. These pigments absorb any moisture that enters the paint film.

Creosote – A liquid coating made from coal tar once used as a wood preservative. It has been banned for consumer use because of potential health risks.

Counterflow – Transporting overflowed solution from one washer stage to another for reuse.

Cratering – Small round depressions on a paint film.

Creepage – Corrosion under a scribe line or edge after salt spray or other testing.

Cross Contamination – A condition when two or more powders are mixed by accident, usually resulting in a reduction in quality.

Cubic Feet Per Minute – Volume movement of a fluid. A measure used to size powder systems based on captive air. If not otherwise defined, the conditions are presumed to be air at a temperature of 68 degrees F, a pressure of 14.70 pounds per cubic foot. In gas industries, the temperature of standard air is usually given at 60 degrees F.

Cure – For thermoset powders, the polymerization of the resins and crosslinkers in the binder system to the desired molecular weight and physical properties of the coating, converting from a dry state to a solid continuous film.

Curing – The process whereby a liquid coating becomes a hard film.

Cyclone – A cylindrical device that separates powder particles from the air stream by centrifugally spinning the particles around its perimeter to the bottom for recovery. Some of the finer particles pass through the cyclone to a collector.

D

Dead Flat – No gloss or sheen.

Decorative Coating – A coating designed primarily for cosmetic appearance and secondarily for protection. Decorative coatings are usually thin films (>5 mils).

Deflector – Conical shaped disc attached to the end of a powder gun to evenly distribute powder in a 360° pattern. Used to shape or direct the powder pattern.

Deionized Water – Water containing no ions other than hydrogen and hydroxyl ions. Usually produced through the use of ion exchange resins and used for rinsing parts after a seal rinse in a spray washer.

Delamination – Separation between two layers of coating or the coating and the substrate.

Delivery – The process of moving the coating powder through the application equipment to the end product.

Diluent – A liquid used in coatings to reduce the consistency and make a coating flow more easily. The water in latex coatings is a diluent. A diluent may also be called a “Reducer,” “Thinner,” “Reducing Agent” or “Reducing Solvent.”

Discoloration – Color change.

DOI – Distinctness of Image. A test used to describe the surface reflectance of a paint film. A mirror would have very high DOI, but a low gloss texture would have no DOI.

Down-draft Booth – A powder booth in which the extraction opening is at the bottom of the booth.

Drag-out – Process of solution entrapment being pulled with the product typically out of a washer zone or coating enclosure.

Driers – Various compounds added to coatings to speed the drying.

Dry Colors – Powder-type colors to be mixed with water, alcohol or mineral spirits and resin to form a paint or stain.

Drying Oil -An oil that when exposed to air will dry to a solid through chemical reaction with air: linseed oil, tung oil, perilla, fish oil, soybean oil.

Dry Film Thickness – Depth of applied coating powder before curing.

E

Earth Pigments – Those pigments that are obtained from the earth, including barite, ocher, chalk and graphite.

Edge Coverage – A coating powder’s ability to flow over, build, and adhere to sharp corners, angles and edges.

Eggshell – Gloss lying between semi-gloss and flat.

Electrode – A metal filament within or at the end of a powder gun, used to create air ions as high voltage is applied. Powder is charged by the attachment of air ions.

Electrostatic Spray Technique – A deposition method of spraying and charging powder so that it is deposited on a grounded substrate.

Emulsion – A mixture of solids suspended in a liquid.

Emulsion Paint – Coating in which resins are suspended in water, then flow together with the aid of an emulsifier. Example: latex paint.

Enamel – Broad classification of paints that dry to a hard, usually glossy finish. Most equipment-coating enamels require baking. Enamels for walls do not.

Environmental Protection Agency (EPA) – Agency of the U.S. Government whose purpose is to regulate and control those agents affecting the environment.

Epoxy – Extremely tough and durable synthetic resin used in some coatings. Epoxy coatings are extremely tough, durable and highly resistant to chemicals, abrasion, moisture and alcohol.

Etching – Surface preparation of metal by chemical process. Removal of a layer of the base metal.

Extender -Ingredients added to paint to increase coverage, reduce cost, achieve durability, alter appearance, control rheology and influence other desirable properties; less expensive than prime hiding pigments such as titanium dioxide. Examples: barium sulphate, calcium carbonate, clay, gypsum, silica, talc. May also improve coating performance.

Extruder – Device used to melt-mix plastics and/or coating powders. An extruder utilizes heat and mechanical kneading to achieve a homogeneous mixture.

F

Fading – Gradual loss of color of a paint film due to a chemical or physical change, usually caused by ultraviolet light.

Fan Pattern – Geometry or shape of spray pattern.

Fan Spray Nozzle – A powder gun tip that provides a fan-shaped spray pattern.

Faraday Cage Effect – A condition that may exist on a substrate due to its geometric configuration that may inhibit the electrostatic application of powder particles at that specific localized area, such as cavities or recesses.

Fatty Edge – Thick film sometimes found on heavily coated work, resulting in a rounded, thicker film along the edges.

Feed Hopper – A container that holds powder for supply to the guns. Most feed hopper designs employ fluidization of the powder for uniform feed to the guns. See Fluidized Bed.

Ferrous – Containing iron.

Filler – Extender, bulking agent or inert pigment.

Film Build – Amount of thickness produced in an application. Millimeters (mils) of dry film per mils of applied wet film.

Film Thickness – Depth of cured coating, usually expressed in mils, 1/1,000 of an inch.

Fines – Small powder particles, usually under 10 microns.

Fire Resistance – The ability of a coating to withstand fire or to protect the substrate to which it is applied from fire damage.

Fire Retardant -A coating that will (1) reduce flame spread, (2) resist ignition when exposed to high temperature or (3) insulate the substrate and delay damage to the substrate.

Fisheye – A large surface depression in a coating film often caused by a contaminant such as oil or silicone.

Flash Rusting – Very thin film of rust occurring within minutes after applying a pretreatment solution.

Flat -A surface that scatters or absorbs the light falling on it so as to be substantially free from gloss or sheen (0-15 gloss on a 60-degree gloss meter).

Flow – Measure of self-leveling; characteristics of a coating allowing it to level or spread into a smooth film of uniform thickness before hardening.

Fluidize – A term that describes powder that is in a state of suspension using compressed air, creating a fluid mixture of air and powder.

Fluidized Bed – A fixed container in which powder is suspended in a continuous stream of air. Preheated objects may be coated by dipping directly into a fluidized bed. The fluidized bed may also be used to facilitate transfer of powder materials to an alternate application site.

Forced Dry – Baking the paint between room temperature and 150° F to speed the drying process.

FPM – Feet Per Minute, a measure of airflow speed.

G

Galvanic Corrosion -an electrochemical process in which one metal corrodes preferentially to another when both metals are in electrical contact, in the presence of an electrolyte.

Galvanized Steel – Steel coated with a layer of metallic zinc.

Galvanizing – Process in which a thin coating of zinc is applied to iron or steel to prevent rust.

Gassing – Air or gas that escapes from a sub-surface beneath a coating and causes blisters, bubbles or small holes in the coating. Gassing frequently occurs with zinc or aluminum castings or galvanized steel and is commonly referred to as out-gassing.

Gauge – Instrument or device for measuring, indicating or comparing a physical characteristic.

Gel Time – Interval required at a given temperature for a powder to be transformed from a dry solid to a gel-like state. Gel time is measured in seconds at a given temperature.

Geysers – Spouts of air and powder found in a fluid hopper when uneven air dispersion is applied.

Gloss -The luster or shininess of paints and coatings. Different types of gloss are frequently arbitrarily differentiated, such as sheen, distinctness-of-image gloss, etc. Trade practice recognizes the following gloss levels, in increasing order of gloss : flat (or matte)– practically free from sheen, even when viewed from oblique angles (usually less than 15 on 60-degree meter); eggshell– usually 20-35 on 60-degree meter; semi-gloss–usually 35-70 on 60-degree meter; full-gloss–smooth and almost mirror-like surface when viewed from all angles, usually above 70 on 60-degree meter.

Gloss Meter – A device for measuring the light reflectance of coatings. Different brands with the same description (such as semi-gloss or flat) may have quite different ratings on the gloss meter.

Gloss Retention – Ability to retain the original gloss.

GPM – Gallons Per Minute.

Grounding – A method of removing or adding electrical charge.

Gun Extension – Extension adapter to a spray gun. Allows for better penetration for manual reinforcement.

H

Hardener – Curing agent for epoxies or fiberglass.

Hardness – The ability of a cured coating to withstand indentation.

HAP – See Hazardous Air Pollutant

Hazardous Air Pollutant -Pollutants that are known or suspected to cause cancer or other serious health effects, such as reproductive effects or birth defects, or adverse environmental effects.

HEPA Filter – High efficiency particulate air-purifying filter. Separates particles down to sub-micron sizes from air.

Hexavalent Chrome – Chromium most often used as a seal rinse in a five- or more stage pretreatment system. Has a +6 valence Hex and is considered a reactive seal rinse.

Hiding Power – The extent to which a powder coating masks the color and pattern of the surface it is applied to at a given film thickness.

Hybrid – An epoxy-modified polyester or an epoxy-modified acrylic thermoset coating powder. Hybrids usually have good over-bake and good application properties.

Hygroscopic – The tendency of a substance to attract or absorb moisture from the air.

I

Impact Fusion – The tendency of finely divided powders to combine with other particles in the application equipment during the application process.

Inert – A material that will not react chemically with other ingredients.

Infrared Radiation – Electromagnetic energy in the infrared region of the electromagnetic spectrum.

Integral Charging – A powder gun that has a low voltage signal supplied to it and steps up the current to high voltage via a cascade multiplier located in the gun barrel.

Intercoat Adhesion – A coating powder’s ability to adhere to previously applied films.

In-place Management – A series of steps used as an alternative to lead-based paint removal. Improves condition of intact lead-based paint to reduce and/or eliminate hazards without total removal.

Intumescence – A mechanism whereby fire-retardant paints protect the substrates to which they are applied. An intumescent paint puffs up when exposed to high temperatures, forming an insulating, protective layer over the substrate.

Iron Phosphate – Conversion coating. Chemical deposition on steel and aluminum for corrosion protection.

Isocyanate Resins – Urethane resins. Isocyanate curing agent which when heated or reacted with hydroxyl functional polymers, give urethane coatings.

L

Lacquer -A fast-drying usually clear coating that is highly flammable and dries by solvent evaporation only. Can be reconstituted after drying by adding solvent. Historical Note: The word lacquer is derived from the word lac, which describes the secretions of the lac beetle. This insect, found mainly in Asia, deposits its secretions on branches of trees and this crop is later harvested. The resin developed by the insects, in its original state, contains a red dye. This dye is separated from the resin by boiling in water. Next the residue resin, known as seed lac, is melted, strained, cooled and flaked and then becomes shellac.

Lance Extension – Variable extensions for powder guns.

Latex-based Paint – General term used for water-based emulsion paints

made with synthetic binders such as 100% acrylic, vinyl acrylic, terpolymer or styrene acrylic. A stable emulsion of polymers and pigment in water.

Lead – A metal, previously used as a pigment in paints. Discontinued in the early 1950s by industry consensus standard, and banned by the Consumer Products Safety Commission in 1978 because of its toxicity.

Linseed Oil – Drying oil made from the flax seed. Used as a solvent in many oil- based paints. “Boiled” linseed oil can be used to protect wood from water damage. Sometimes used as a furniture polish.

Liquid Driers – Solution of soluble driers in organic solvents.

Lithopone – A white pigment of barium sulfate and zinc sulfide. Historical Note: Lithopone was once a primary substitute for lead carbonate or “white lead” pigments; it has been largely replaced by titanium dioxide.

Lower Explosive Limit (LEL) – The lower point for a range of concentrations or organic particles suspended in air, which can be ignited by a sufficient energy source. Also referred to MEC or Minimum Explosive Concentration.

M

Magnehelic Gauge – Trade name of Dwyer Instruments’ gauge for measuring air pressure in inches or water column.

Mandrel Bend Test – Physical bending test for testing flexibility. (ASTM Test D522)

Marine Paint – Coating specially designed for immersion in water and exposure to marine atmosphere. (See also Anti-fouling Paint)

Masking – Covering areas of a part to prevent coverage by powder during application.

Material Safety Data Sheet (MSDS) – Information supplied by coating manufacturers listing all known hazardous ingredients, physical and health hazards, first-aid procedures and protective equipment.

Material Utilization – The percentage of a volume of powder that actually is deposited on the parts, not lost through handling, transfer onto the racks, contamination or as non-reclaimed powder.

Matte – A surface with minimal reflection of light, the opposite of high gloss.

Melt Mixing – A predominant process for the manufacture of coating powders involving the continuous compounding of the pigments, fillers, catalysts and resins at elevated temperatures.

Mil – A measurement of film thickness, 1 mil = .001′.

MIL-DTL – A specification that specifies design requirements, such as materials to be used, how a requirement is to be achieved, or how an item is to be fabricated or constructed. A specification that contains both performance and detail requirements is still considered a detail specification.

MIL-SPEC – United States Military Defense Standard or sometimes referred to as “military standard” (MIL-STD) or MIL-SPEC or informally, “MilSpec,” is used to help achieve standardization objectives by the U.S. Department of Defense.

MIL-STD – A document that establishes uniform engineering and technical requirements for military-unique or substantially modified commercial processes, procedures, practices, and methods. There are five types of defense standards: interface standards, design criteria standards, manufacturing process standards, standard practices, and test method standards. MIL-STD-962 covers the content and format for defense standards.

Mild Steel – Structural steel or plate, malleable iron based alloy. SAE 1020, with a carbon content of up to 2.5%.

Mileage – Term used to describe the amount of area that can be covered with a given amount of coating material. Measured in ft2/lb.

Mill Scale – Oxide layer formed on steel by hot rolling process.

Mineral Spirits – Paint thinner. Solvent distilled from petroleum.

Molten Salt – Inorganic chemical or chemicals that are used at temperatures above their melting point as heat transfer, heat treating or metal cleaning purposes.

Molten Salt Bath – A specially designed vessel used to contain and heat molten salt processes.

Monomer – Substance composed of low molecular weight molecules capable of reacting with like or unlike molecules to form a polymer.

N

Naphtha – A petroleum distillate used mostly by professionals (as opposed to do-it- yourself painters) for cleanup and to thin solvent-based coatings. A volatile organic compound (see VOC).

National Fire Protection Association (NFPA) – An organization that has developed a system for indicating the health, flammability and re-activity hazards of chemicals.

Natural Resins – Resins from trees, plants, fish and insects. Examples: damars, copals.

Non-Ferrous – A material containing no iron.

Nonvolatile – The portion of a coating left after the solvent evaporates; sometimes called the solids content.

Nylon – A thermoplastic powder coating which contains long-chain polymers consisting of recurring amide groups (CONH). These coatings are tough, abrasion-resistant and exhibit good chemical resistance.

O

OEM – Original Equipment Manufacturer.

Off-color – Not matching the color standard to which the coating is being compared.

Ohm – A unit of electrical resistance.

Oil Paint – A paint that contains drying oil, oil varnish or oil-modified resin as the film-forming ingredient. The term is commonly and incorrectly used to refer to any paint soluble by organic solvents.

Oleoresin – A natural plant product that contains oil and resins. Turpentine is an example.

Opacity – Ability to hide the substrate of a given film thickness.

Orange Peel – A wavy irregularity in the surface of a paint film coated by the flow characteristics of the coating. Orange peel appears as a characteristically uneven or rough surface to the eye, but usually feels smooth to the touch.

(Orange Peel)

(Orange Peel)

Organic – Substance containing carbon compounds.

Organic Powder – That which was derived from carbon atoms containing compounds such as epoxies, polyesters, hybrids, vinyls, nylon, phenolics, etc.

Oscillator – Device used to move automatic guns in a vertical plane to provide uniform and increased powder coverage. Motion is provided by a wheel and arm mechanical device within the unit. Radial oscillators, or wagglers, move the guns in an arc motion.

Overall Efficiency – The product of the compression efficiency and the mechanical efficiency.

Over-atomized – Powder that has been dispersed too finely but by use of excessive atomizing air pressure.

Overbake – Applying more heat in time and/or temperature than is required for cure. Overbake is the result of curing paint film at too high of a combination of time and temperature. The film often becomes too hard and may embrittle and/or color and gloss may be adversely affected.

Overspray – Material that does not deposit on the part of rack and goes to the recovery system

Oxidation – Chemical reaction upon exposure to oxygen. Some coatings cure by oxidation, when oxygen enters the liquid coating and cross-links the resin molecules. This film-forming method is also called “Air Cure” and “Air Dry.” (Oxidation also causes rust on bare metals.)

P

Paint – A coating including resin, a solvent, additives, pigments and, in some products, a diluent. Paints are generally opaque, and commonly represent the portion of the industry known as “architectural coatings.”

Paint Remover – A chemical that softens old paint or varnish and permits it to be easily scraped off. Also called “stripper.”

Part Bring-up Time – Amount of time required to heat a part to a desired metal temperature.

Part Opening – The opening in the powder booth, ovens, washers and other equipment where parts enter and exit.

Particle Size – The average diameter of an object having irregular boundaries that can be determined to have diameter through various test methods.

Passivation – Conversion of a metal surface to a less reactive state. A process used to reduce the corrosion rate of metal surfaces.

Penetrating Finish – A finish that sinks into the substrate, as opposed to settling on the surface.

pH Value – Measure of acidity or alkalinity. pH7 is neutral. The pH values of acids are less than 7. The pH values of alkali bases are greater than 7.

Phosphate – Chemical radical (PO4)-3. In coating operations, zinc, iron or manganese phosphate is used as a conversion coating to prepare the part for coating application.

Pigment – Particles in a powder formula that provide color, corrosion resistance and other properties.

Pinholing – Formation of small holes through the entire thickness of a coating. The appearance of fine, pimply defects in a cured film, due to air trapped under the surface of the film or other causes, resulting in small holes in the film.

Polyester – A resin or powder containing the chemical group R-COOC-R.

Polyethylene – A thermoplastic resin with the formula (CH2CH2)x.

Polymer – Substance, the molecules of which consist of one or more structural units repeated any number of times; vinyl resins are examples of true polymers.

Polymerization – The interlocking of molecules by chemical reaction to produce very large molecules. The process of making plastics and plastic-based resins.

Polypropylene – One of the more common polyolefin thermoplastics. An addition polymer from propylene monomers with a crystalline structure (CH2CHCH2)x.

Polyvinyl Chloride – A synthetic resin used in the binders of coatings. Tends to discolor under exposure to ultraviolet radiation. Commonly called “vinyl.”

Porosity – Degree of integrity or continuity.

Post-Consumer Paint Management – The following steps are recommended for dealing with post-consumer (leftover) paint:

-

Purchase the correct amount of paint

-

Store paint properly

-

Use leftover paint

-

Reuse (donate) or recycle

-

Dispose of paint properly (a last resort)

Post-curing – Heating of a part after powder coating to complete the cure cycle, which completes the cross linking of the components.

Power & Free Conveyor – Two-track chain conveyor system that allows product to be transported at different speeds and through different routes throughout the finishing system.

Powder – A coating blend made of non-volatile ingredients, applied dry and melted into a continuous film.

Powder Booth – An enclosure used for containment of powder during the spray operation.

Powder Coating – Coatings that are protective, decorative, or both, formed by the application of a coating powder to a substrate and fused into continuous films by the application of heat or radiant energy. Coating powders are finely divided particles or organic polymer which generally contain pigments, fillers and additives; and which remain finely divided during storage under suitable conditions.

Pressure – Force per unit area relative to atmospheric pressure. Usually expressed in pounds per square inch.

Pretreatment – The preparation of a part prior to the application of powder coating in order to improve adhesion and corrosion resistance.

Primer – A type of coating, usually paint, applied to a surface to improve adhesion of a top coat and/or improve corrosion resistance.

Primer Surfacer – Coating used to prime a surface as well as fill irregularities in the substrate. Primer surfacers are usually applied over a primer.

Production Rate – Measurement of square foot per day of the surface area cleaned or coated in one working day by one person.

Profile – Surface contour of a blast-cleaned surface as viewed from the edge cross-section of surface.

Profile Depth – Average distance between top of peaks and bottom of valleys on a surface.

Propellant – The gas used to expel materials from aerosol containers.

PSI – Pounds per square inch, a measure of force above a vacuum.

Pump – Device that converts mechanical force and motion into hydraulic fluid powder.

Pump Screen – A screen that catches large contaminants in a process solution as the solution flows through it to the pump.

Purging – Cleaning one color or powder formulation from all areas that come in contact with the powder before introducing another color or powder.

R

Radiation Cure – Curing a coating by means of exposure to electromagnetic waves or particles such as infrared, ultraviolet or electron beam.

Reciprocator – Device used to move automatic guns in a vertical plane. Motion is provided by a reversing or reciprocating drive system.

Reclaim – The process used to recycle nondeposited powder through the delivery system for reuse.

Reclaimed Powder – Powder which has been oversprayed and captured for reuse.

Recoat – Process of refinishing parts that have a surface defect from the first coating application by repairing the defect and respraying.

Recovery – The process of removing nondeposited powder from the air prior to recirculating the powder through the delivery system.

Recovery System – A filtration system that separates powder from the airstrip with a fan that captures oversprayed powder and maintains negative air pressure inside a powder booth. Most common type of recovery systems are the cyclone system and the cartridge module system.

Resin – Synthetic or natural material used as the binder in coatings. Can be translucent or transparent, solid or semi-solid. Examples: acrylic, alkyd, copal ester, epoxy, polyurethane, polyvinyl chloride, silicone.

Resistivity – The resistance to the flow of electrical current afforded by a substance.

Reverse Osmosis – Method of removing metal ions from an aqueous solution via semi-permeable membranes.

Rework – Procedures to correct powder coating imperfections or defects.

Rosin – Natural resin obtained from living pine trees or from dead tree stumps and knots.

Runs – Sags in the coating.

Rust – Corroded iron. Red iron oxide deposited on metal. Also other metal oxides formed by corrosion.

S

Salt Spray Test – Corrosion test using salt (NaCl) solution sprayed as a mist in a heated humidity chamber to simulate seashore conditions, or to accelerate corrosion at a controlled rate. (ASTM Test B117)

Sand Blast – Blast cleaning using sand as an abrasive.

Sanitary Pan – A trough that is mounted under a conveyor chain to catch debris and keep it from falling on work in progress.

Scale – Rust occurring in layers, commonly found on hot-rolled steel.

Screen Mesh Size – The mesh number of a screen designates the openings per square inch using standard wire. Screens are used to classify the size of the coating powders.

Seal Rinse – A final rinse in a spray washer that passivates the pretreated surface to prevent oxidation and provide corrosion resistance in the field.

Seeding – Formation of small agglomerates or gel particles. Seeds in coating powders can form when the material is overheated during the extrusion process.

Semi-gloss Finish – Finish that has a low luster sheen. Semi-gloss paints are formulated to give this result (usually 35-70 degrees on a 60-degree meter).

Shelf Life – Maximum amount of time a material may be stored and still be in usable condition.

Shellac – A coating made from purified lac dissolved in alcohol, often bleached white.

Shot Blasting – Blast cleaning using steel shot as the abrasive.

Side-draft Booth – A powder booth where the air extraction opening is on the side of the booth.

Sieve – Powder particle classifier which utilizes wire mesh of various sizes to screen out oversized powder particulate and foreign material or dirt. (Rotary Sieve – Cylindrical screen equipped with an electrically driven paddle used to classify powders, or remove undesirable particulate from powder materials. Vibratory Sieve – Electrically or pneumatically driven screen utilizing vibration to classify powders, or remove undesirable particulate from the powder materials.)

Silicone – A resin used in the binders of coatings. Also used as an additive to provide specific properties, e.g., de-foamer. Paints containing silicone are very slick and resist dirt, graffiti and bacterial growth, and are stable in high heat.

Sintering – The tendency of some powders and powder coating materials to agglomerate during storage.

Soils – Foreign matter on a part’s substrate prior to being cleaned in a pretreatment system. Can be organic or inorganic.

Solids – The part of the coating that remains on a surface after the vehicle has evaporated. The dried paint film. Also called Nonvolatile.

Solvent – Any liquid that can dissolve a resin. Generally refers to the liquid portion of paints and coatings that evaporates as the coating dries.

Solvent-borne Coating – Coating containing only organic solvents. (Non-water-borne)

Source Reduction – Steps taken to reduce waste generation and toxicity at the source through more effective utilization of raw materials and reformulation.

Specific Gravity – An expression of density of a material relative to water. Examples: water – 1.000; ammonia – .587; propane – 1.550; natural gas – .665. Ration of the weight of a given volume of liquid or solid to the weight of an equal volume of water. (ASTM Test D3451)

Specular Gloss – Mirror-like finish (usually 60 degrees on a 60-degree meter).

Spray Pattern – Configuration of spray with a powder gun. See Diffuser and Fan Spray Nozzle.

Spray-to-waste Operation – Utilizing virgin powder only. All overspray powder is discarded and not recycled.

Storage Life – Period of time that a powder material will remain usable in storage.

Storage Stability – The ability of coating powders to maintain uniform physical and chemical properties after being subjected to the manufacturer’s specified storage conditions.

Substrate – Any surface to which a coating is applied.

Surface Defects – Flaws in the surface of a coated part.

Surface Preparation – Operations necessary to prepare the surface of a part prior to the application of a coating.

Surfactant – Chemical used to adjust surface tension of a material.

Surge – (1) A rise of pressure in an electrical circuit. (2) A sudden burst of powder from the spray gun.

T

Thermal Spray – A group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten condition to form a coating. The coating feedstock may be in the form of a powder, rod or wire.

Tie Coat – A paint specifically formulated for specific situations and conditions to provide a transition from a primer or undercoat to a finish coat. Tie coats are used to seal the surface of a zinc-rich primer, to bond generically different types of coatings, or to improve the adhesion of a succeeding coating.

Titanium Dioxide -White pigment in virtually all white paints. Prime hiding pigment in most paints.

Turpentine -Distilled pine oil, used as a cleaner, solvent or thinner for oil-based and alkyd coatings.

U

Urethane – An important resin in the coatings industry. A true urethane coating is a two-component product that cures when an isocyanate (the catalyst) prompts a chemical reaction that unites the components.

V

Vehicle – Portion of a coating that includes all liquids and the binder. The vehicle and the pigment are the two basic components of paint.

Viscosity – The property of a fluid whereby it tends to resist relative motion within itself.

Volatility – The defining quality of a liquid that evaporates quickly when exposed to air.

Volatile Organic Compound – Organic chemicals and petrochemicals that emit vapors while evaporating. In paints, VOC generally refers to the solvent portion of the paint which, when it evaporates, results in the formation of paint film on the substrate to which it was applied.

Volume Solids – Solid ingredients as a percentage of total ingredients. The volume of pigment plus binder divided by the total volume, expressed as a percent. High-volume solids mean a thicker dry film with improved durability.

W

Water-based – Coatings in which the majority of the liquid content is water.

White Lead – Lead carbonate

(Back Ionization)

(Back Ionization)

(Orange Peel)

(Orange Peel)