Decorative Coatings Metal Substrates

|

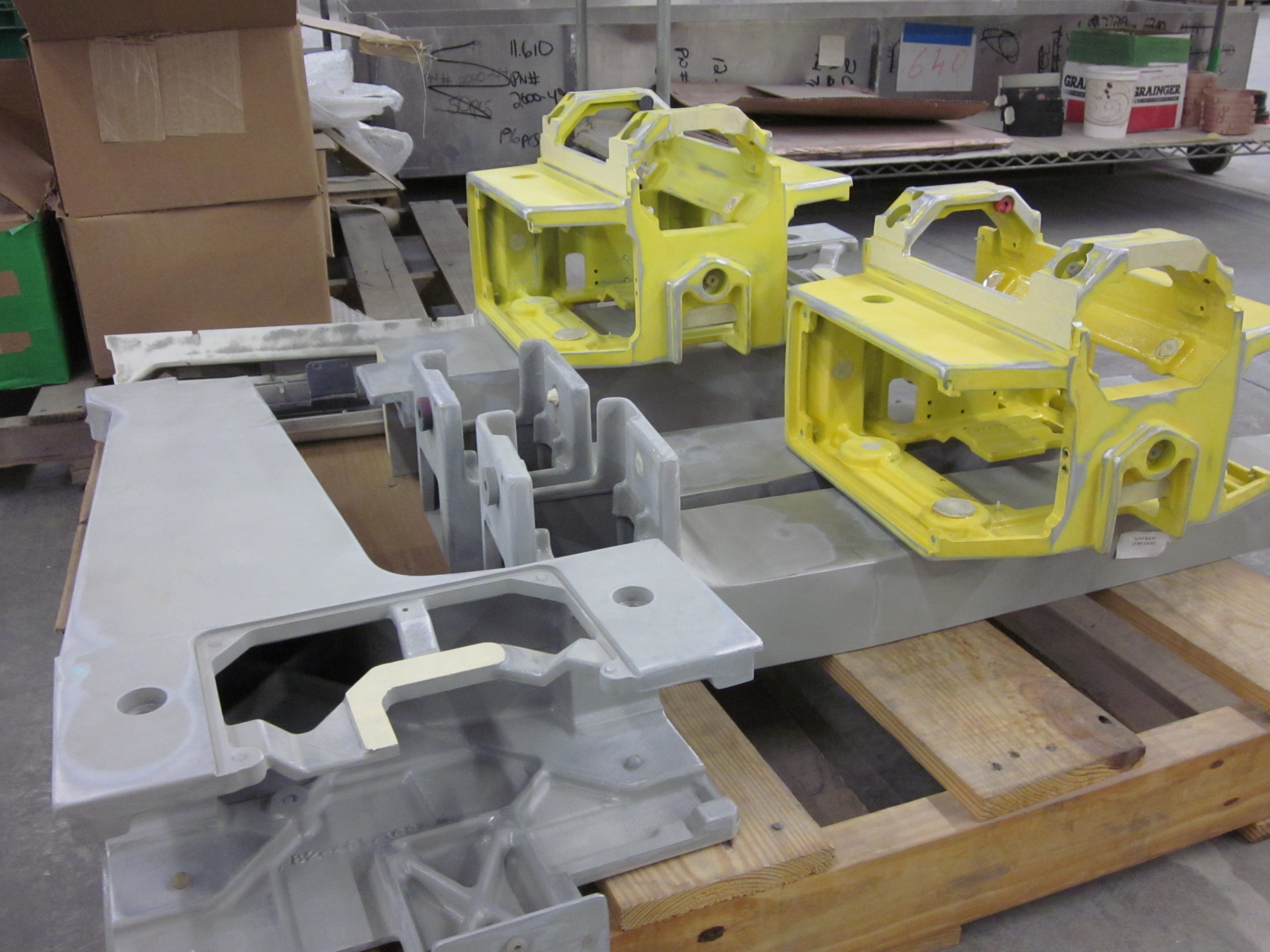

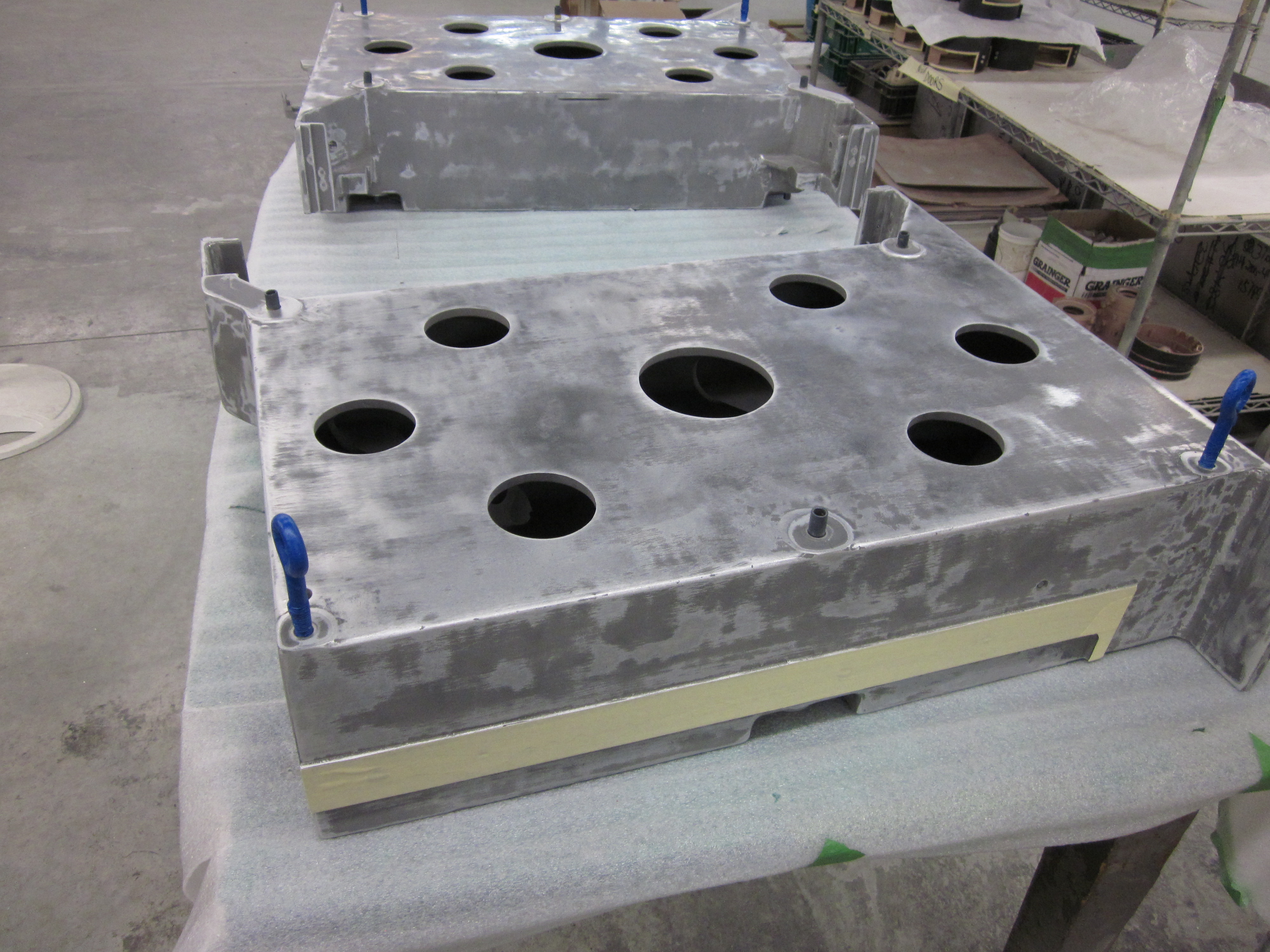

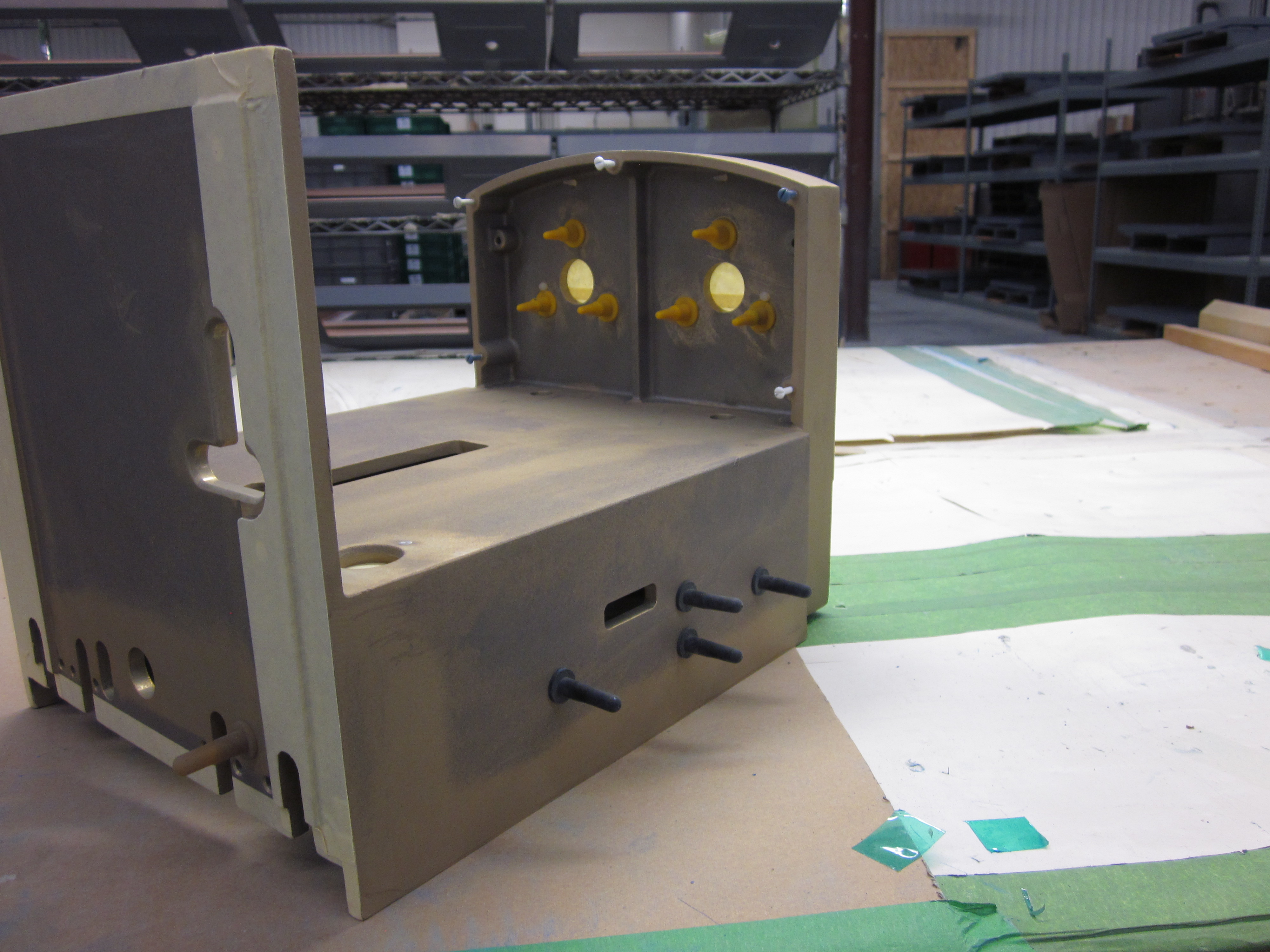

Decorative coating on metal components performed at Consolidated Coating Company is attractive and protective in both smooth (color) coats and/or texture coats. From simple to complex parts, we apply these coatings with the same attention to customer requirements. Painting and/or powder coating of metal substrates in small or large quantities is just one of our areas of expertise.

|

Capabilities

-

Substrates Coated

Alloys

Aluminum

Cold rolled steel -

Coatings Used

Catalyzed Polyurethanes

Catalyzed Epoxy -

Work Envelope

-

Secondary Operations

Masking

Filling/Sanding

Silk Screening of Logos -

Industries Served

Telecommunications

Security

Gaming

Medical Instrumentation

Computer

Semiconductor

Aerospace

Fire Protection

Sporting Equipment

Laboratory Testing Equipment

Life Sciences -

Value Added Services

Short term storage of finished or unfinished products

Production planning and delivery schedules

Free local deliveries by our own transport facilities -

Equipment List

5 Overhead Conveyor Systems

13 Spray Booths